Industry

Industria 4.0

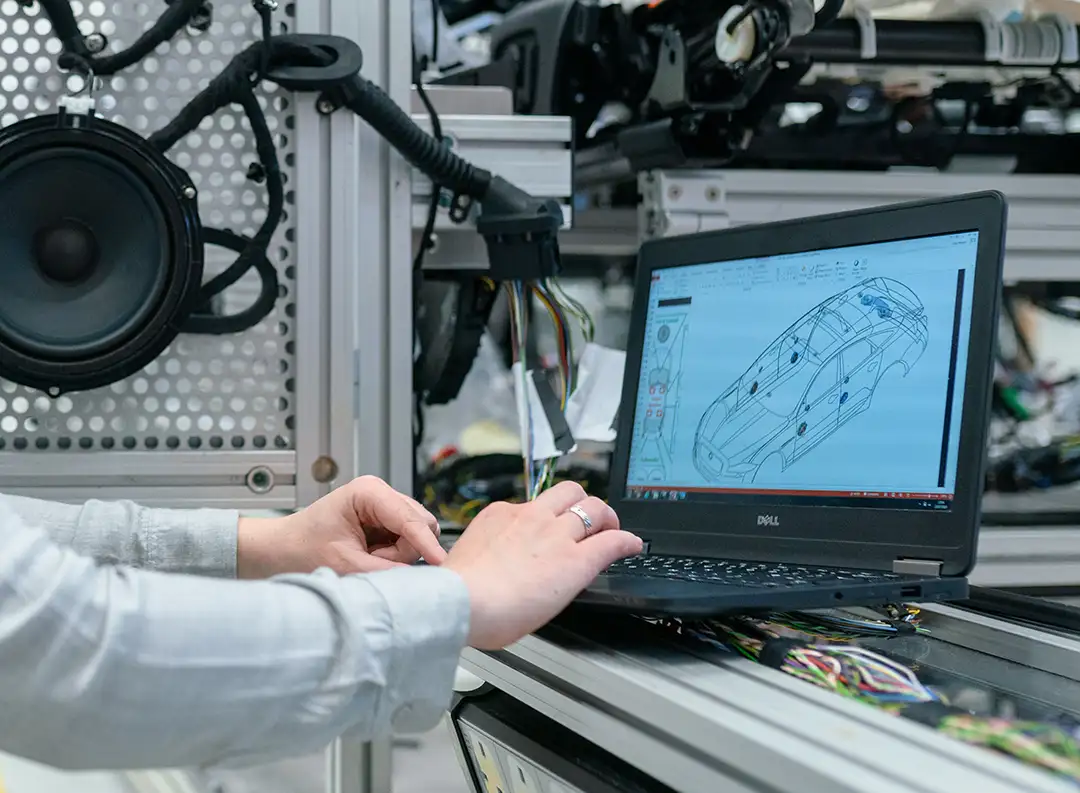

La tua azienda è pronta a entrare nell'era dell'industria 4.0? L'avvento di tecnologie digitali avanzate per trasformare i processi di produzione e creare "fabbriche intelligenti" è una prospettiva che può aumentare significativamente l'efficienza, la flessibilità e la qualità nella produzione, consentendoti di adattarti rapidamente alle mutevoli esigenze del mercato e di offrire prodotti o servizi su misura.

L'Internet of Things (IOT) favorisce la connessione e la comunicazione tra macchinari, ottimizzando l'efficienza e consentendo la raccolta di dati in tempo reale. La digitalizzazione, l'intelligenza artificiale e la robotica contribuiscono a migliorare l'analisi dei dati, supportando decisioni informate, strategie predittive e aumentando la produttività. Una concezione multidisciplinare per ottimizzare i processi aziendali e renderli capaci di auto-ottimizzarsi, prevedendo guasti o problemi di produzione prima che si verifichino e adattandosi in tempo reale alle variazioni nella domanda.

Porta l'automazione, la connettività e i nuovi sistemi digitali nella tua pratica industriale: siamo al tuo fianco per creare un ambiente produttivo più efficiente e competitivo.

"Le nuove tecnologie stanno rivoluzionando i processi produttivi. L'Internet of Things (IOT) favorisce la connessione e la comunicazione tra macchinari, ottimizzando l'efficienza e consentendo la raccolta di dati in tempo reale.

La digitalizzazione, l'intelligenza artificiale e la robotica contribuiscono a migliorare l'analisi dei dati, supportando decisioni informate, strategie predittive e aumentando la produttività."